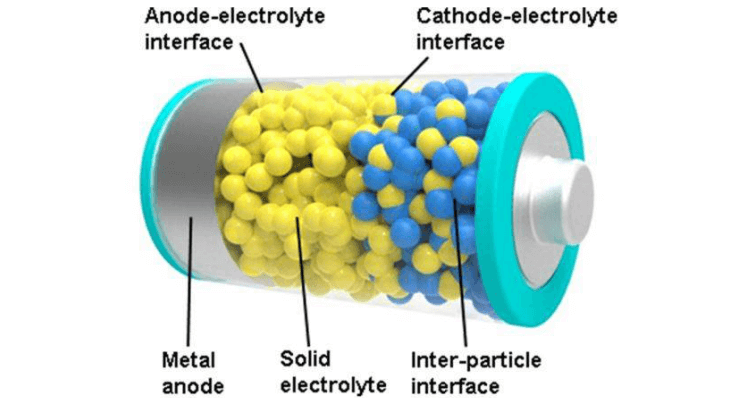

If we put it plainly, an all-solid-state battery is a battery that has no gas and no liquid in it, and all materials exist in a solid state.

Considering that the most common battery in people’s daily life is lithium batteries, we will default to “all-solid-state lithium-ion batteries” as representatives of all-solid-state batteries (ignoring new-type batteries such as solid-state lithium-sulfur for the time being).

Generally speaking, a lithium-ion battery is mainly composed of a positive electrode, a negative electrode, a separator, an electrolyte, a structural case, and the like. The electrolyte allows current to be conducted in the form of ions inside the battery.

Electrolyte technology is one of the core technologies of lipo batteries, and it is also a very profitable component in the battery industry.

However, many people may find that some lithium batteries will swell after a long time, and in even more extreme small probability events, some may even be dangerous.

In addition, in general, the operating temperature range of current lithium-ion batteries is limited, and the life will be shortened sharply at high temperatures above 40 degrees, and the safety performance will also have great problems (so Tesla MODEL S will have a strict battery Temperature control system is just for this).

In fact, the above-mentioned several safety issues are directly related to the electrolytes of the organic systems used in our batteries.

In order to solve the problem of battery safety and increase energy density, the research and industrial circles are currently developing and producing all-solid-state batteries, that is, replacing the separator and electrolyte of traditional lithium-ion batteries with solid electrolyte materials.

Then, what are the advantages of all solid-state batteries compared to the most common lithium-ion batteries in our lives?

First, we need to know–

What are the main factors affecting the safety of ordinary lithium ion batteries?

1) Electrode material characteristics, such as the possibility of lithium dendrites working under large currents, which could puncture the diaphragm and cause short-circuit damage;

2) The electrolyte is an organic liquid, and the tendency of side reactions, oxidative decomposition, gas generation, and combustion at high temperatures will increase;

3) The battery quality is uneven, especially the battery safety performance of small manufacturers is not up to standard;

4) The battery management system is unqualified, causing overcharging and discharging of the battery, leading to danger.

If all-solid-state battery technology is used, the above problems 1 and 2 can be directly solved, and the maximum operating temperature of the obtained battery can be increased from the current 40 degrees to a higher level, so that the battery can adapt to work. The wider the temperature range, the wider the application range.

Safety is actually one of the most fundamental driving forces for the development of all-solid-state batteries. Let’s talk about the advantages of solid-state batteries

What are the advantages of solid-state batteries?

Thin-small size

In fact, the volume energy density is a very important parameter for the battery. If it is in the application field, the requirements are from high to low: consumer electronics> home electric cars> electric buses.

In popular terms, the volume energy density is high, so batteries of the same quality can be made smaller.

The available space in electronic products is often limited, and many products (such as mobile phones and tablet computers) have almost 1/3 of their volume and quality already occupied by the battery, and manufacturers and consumers want to further increase the capacity of the battery (increase Under the requirements of battery life and compact volume (portable and beautiful and easy to design), high-density lithium cobalt oxide (LCO) batteries with the highest volume energy density are still the mainstream products.

In traditional lithium-ion batteries, a separator and an electrolyte are required, which together occupy nearly 40% of the volume and 25% of the mass in the battery.

If they are replaced with solid electrolytes (mainly organic and inorganic ceramic materials), the distance between the positive and negative electrodes (conventionally filled with a separator electrolyte and now filled with a solid electrolyte) can be shortened to even a few to A dozen microns, so that the thickness of the battery can be greatly reduced-so all-solid-state battery technology is the only way for battery miniaturization and thin film.

Not only that, many all-solid-state batteries prepared by physical / chemical vapor deposition (PVD / CVD) may have a thickness of only a few tens of micrometers, so they can be made into very small power devices and integrated into MEMS (microelectromechanical systems) In the field.

The ability to make very small batteries is also a major feature of all-solid-state battery technology, which can facilitate the battery to adapt to the application of various new small-sized smart electronic devices. At this point, traditional lithium-ion battery technology is difficult to achieve. of.

One of the key obstacles to the practicality of many nanomaterials today is the large specific surface area and the low bulk density. If products based on these materials are made, they often occupy too much volume at the same mass, that is, the volume energy density is too low to meet the general requirements. Requirements for industrial products.

Therefore, it is not difficult to understand why the parameters of this aspect are often not selected in the research of nanometer (battery) materials.

The prospect of flexibility

The all-solid-state battery can be further optimized to become a flexible battery, which brings more functions and experience.

In fact, even brittle ceramic materials can often be bent after the thickness is less than millimeters, and the material will become flexible.

Correspondingly, the all-solid-state battery will have a significantly improved flexibility after being thinned. By using appropriate packaging materials (not a steel case), the battery can be subjected to hundreds to thousands of bends to ensure that The performance is basically not degraded.

In fact, flexible electronic devices represented by various wearable devices are an important direction for the development of next-generation electronic products, and this requires that the components in the product also need to be flexible, so flexible all-solid-state batteries are in the scientific and industrial circles. , Very promising star of tomorrow.

Not only that, the potential of functional all-solid-state batteries is far more than that of flexible batteries. The optimized battery material structure can be used to make transparent batteries, or stretchable batteries that can stretch up to 300%, or can be integrated with photovoltaic devices. Integrated power generation-storage integrated devices, etc.-There are still many innovative applications in terms of functions meant by all-solid-state batteries. In this regard, the imagination of scientific researchers and engineers will bring us more and more surprises.

More secure

As an energy storage device, virtually all batteries are virtually impossible to be absolutely safe in thermodynamics.

However, the factors that determine the true safety of batteries in practical applications are various. The influencing factors include the characteristics of battery electrode materials, the properties of electrolytes, and battery management systems in electronic products.

At present, the safety of general commercial lithium ions is the focus of everyone’s attention. Here, “not ideal” is used to evaluate the safety of current batteries, which should be a more appropriate evaluation.

Light-high energy density

After using all-solid-state electrolytes, the applicable material system of lithium-ion batteries will also change. The core point is that it is not necessary to use lithium-doped graphite negative electrodes, but to directly use metal lithium as the negative electrode, which can significantly reduce the negative electrode material The amount of use makes the energy density of the entire battery significantly improved.

In addition, many new high-performance electrode materials may not have good compatibility with existing electrolyte systems before, but this problem can be alleviated after using all-solid-state electrolytes.

Taking the above two factors into consideration, compared with ordinary lithium-ion batteries, the energy density of all-solid-state batteries can be greatly improved: Now in many laboratories, small-scale batch production of energy densities of 300-400Wh / kg all-solid-state battery (generally lithium-ion battery is 100-220Wh / kg).

Challenges

The development of solid-state batteries is currently facing many challenges. Since the electrolyte materials of solid-state batteries are all solid and the conductive process is point contact, the problem based on interface impedance needs to be solved in the battery manufacturing process.

In addition, because all batteries will undergo volume expansion and contraction during charging and discharging, the tolerance of liquid batteries is large, but solid batteries may crack. As far as the current state of technology is concerned, There is still much room for improvement in circulation equipment.

First problem:

the cost is still high, the preparation process is complicated, and the technology is not mature enough

At present, the electrolyte of all solid-state lithium batteries mainly includes organic and inorganic systems, and the cost is generally high. In particular, many batteries of inorganic systems are prepared by complex processes such as CVD / PVD. The production (deposition of thin films) is slow and expensive. The capacity of a single battery is very small, and it is often only suitable for batteries for small electronic devices.

Not only that, the maturity of the current production technology of all solid-state batteries is generally average, and the number of companies capable of forming large-scale production capacity is very limited. There are still many difficulties to be overcome in the scale-up of technology, and it is still in the development phase.

Second problem:

fast charging is not realistic

At present, the rate performance of all-solid-state batteries is generally low, the internal resistance is large, and the voltage drop during high-rate discharge is large. It is basically impossible to expect this type of technology to solve the problem of fast battery charging in the near future.

At present, some products using all-solid-state batteries on the market do not actually work at room temperature. The most typical example is more than 3,000 taxis that use all-solid-state batteries in France (the energy density of the battery can reach 260Wh / kg, which is better than ordinary lithium-ion batteries currently in commercial use).

Third problem:

temporarily unable to commercialize on a large scale

As a senior expert in electric vehicle batteries, Menaheim Undermann, President of Full Battery Consulting, said: “Currently, the solid-state batteries used in electric vehicles are still in the research stage, and it is not possible to determine the timetable for commercialization. It is unlikely that the various chemical materials used in lithium-ion batteries will be selected, and the price is expected to be very high, and mass production will be difficult. ”

In addition, although Toyota said that the charging time of solid-state batteries is twice as long as that of lithium batteries, at the same time, the performance of solid-state batteries is extremely susceptible to temperature. In other words, solid-state batteries are likely to achieve true fast-charge effects at slightly higher temperatures.

Therefore, many in the industry are also skeptical of Toyota’s plan, thinking that Toyota’s mass production of solid-state battery packs is not difficult.

These statements seem to verify Musk’s claims that “solid-state battery technology is not on the road, and is still in the research and development stage.”

Enterprise solid-state battery layout

Many start-ups and traditional industrial giants have already invested in the all-solid-state battery industry.

Bolloré of France, Sakti3 of the United States and Toyota of Japan have high technological maturity and deeper technological accumulation. These three companies also represent the typical technology development direction of the three solid electrolytes of polymer, oxide and sulfide.

Bolloré, which is more famous in Europe, uses a polymer electrolyte system, while Samsung uses a sulfide electrolyte system. British Regal James Dyson acquired the solid-state battery company Sakti3 in 2015. In August 2016, Dyson said it would invest $ 1.4 billion to build a battery factory. German auto parts giant Bosch (BOSCH) acquired the American battery company “Seeo” in 2015. Bosch and Seeo then set up a new factory with Japanese famous GS YUASA (Yuasa) battery company and Mitsubishi Heavy Industries, focusing on solid-state anode lithium-ion batteries.

In general, all-solid-state batteries are one of the mainstream directions for the next step in battery development recognized by the battery research and industry circles, but specific to the solid-state electrolyte’s conductivity, battery rate, battery preparation efficiency, cost control, and all-solid-state batteries. The battery still has some way to go.